- Manufacturing

- Distribution

- Line Card (PDF)

- Eaton/Cutler-Hammer

- Variable Frequency Drive

- Circuit Breakers

- Contactors, Starters & Protective Relays

- Counters, Panel Meters, Tachometers & Timers

- Integrated Power Assembles

- Medium Voltage Motor Control Assemblies

- Metering Devices, Protective Relays & Communications

- Operator Interface Products

- Panelboards

- Power Breakers, Contactors & Fuses

- Power Conditioners, Power Factor Capacitors & Harmonic Filters

- Pushbuttons

- Reduced Voltage Motor Starters

- Sensors

- Switchboards

- Switches

- Switchgear

- Terminal Blocks, Fuse Blocks and Fuse Holders

- Uninterruptible Power Supplies (UPS)

- Timers & Relays

- Transformers

- Hammond Power Solutions (HPS)

- Hammond Manufacturing

- Hubbell/Killark

- Red Lion Controls

- Sprecher + Schuh

- Toshiba

- WEG

- Other Manufacturers

- Cordyne Motor Starters

- Industries Served

- Alternative Energy

- Automation

- Commercial Construction

- Dredging & Aggregates

- Drilling

- Farm & Agriculture

- Food & Beverage

- HVAC

- Industrial Machinery

- Irrigation

- Marine

- Mining

- Nuclear Power

- Oil & Gas

- Petrochemical & Refining

- Process & Well Control

- Pulp & Paper

- Telecommunications

- Traction

- Utilities

- Water Treatment & Sewage

- About Us

- Resource Center

- store

- Contact Us

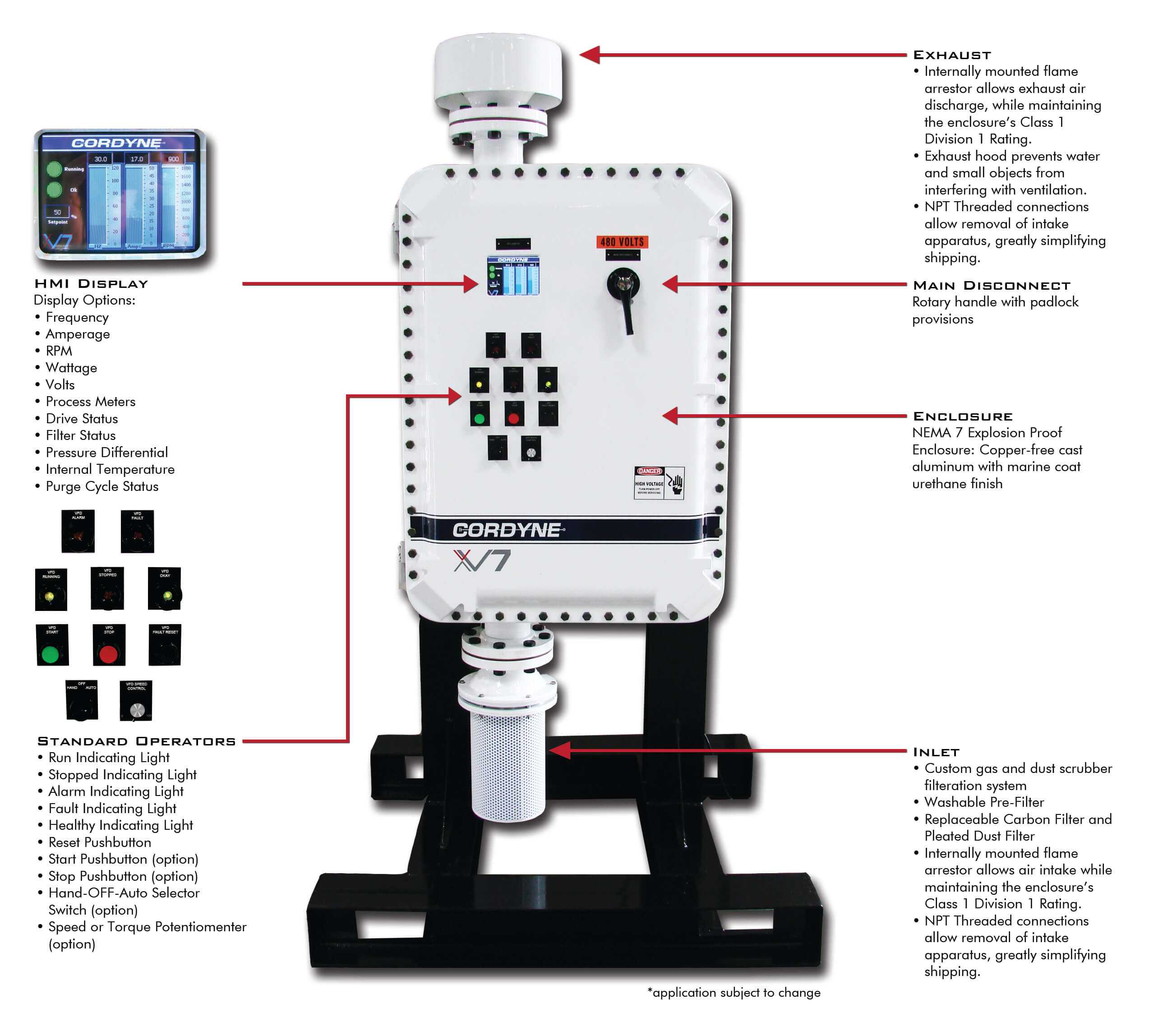

NEMA 7 Explosion Proof Variable Frequency Drive XV7 Series

Background

It is no secret that in modern-day industrial applications, efficiency and precision are becoming absolute necessities regarding motor control. Variable Frequency Drives (VFD’s) have become widely accepted as an excellent means by which companies can facilitate these needs. However, precision motor control within hazardous environments has presented problems for years. Until now, options have been hampered by the need for compressed air, high installation costs, and a lack of locational flexibility. Fortunately, a new solution has been developed to make these problems a thing of the past.

The Solution

We are proud to offer our state-of-the-art XV7 Series. By encapsulating a VFD in a NEMA 7 explosion-proof enclosure, we are able to create a safe area in which the VFD is not at risk of igniting the surrounding atmosphere. The key to this ground-breaking design lies within the ventilation system. Our proprietary design allows ventilation to be achieved, but should an explosion occur within the panel, flames will not escape and ignite the surrounding atmosphere.

Benefits

In addition to the numerous benefits that a VFD imparts on a motor (precise control, increased efficiency, and longer life expectancy), Our XV7 Series brings a number of operational benefits to the table.

- Can be mounted in whatever is deemed as the ideal location

- Substantial increase in operator efficiency

- Less travel time to and from enclosure

- Better view of that which is being controlled

- Wire and conduit from the drive to the motor are greatly reduced, reducing installation time and cost.

- Compressed air is not needed, meaning:

- New air hoses do not need to be run, reducing installation time and cost.

- Compressor downtime translates to drive downtime. Elimination of the compressor means elimination of its downtime, reducing the total downtime of the drive